Understanding Corrosion in Oil-Burning Appliance Chimneys: Causes, Prevention, and Solutions

When we think about caring for our oil-burning appliances, we often forget the chimney. It’s easy to focus on the appliance itself. But the chimney plays an important role too. Regular maintenance of the chimney helps keep everything working well. It also ensures safety for your home and family. However, corrosion in the chimney can cause big problems. It can make the system less efficient and even create safety risks. Understanding how and why corrosion happens is key to keeping our homes safe. It also helps ensure our appliances work properly.

Corrosion in chimneys for oil-burning appliances isn’t just a small problem. It can block airflow, reducing heating efficiency and causing dangerous carbon monoxide leaks. If we understand what causes corrosion, we can prevent it. This will help protect our homes and keep our appliances working well.

In this article, we’ll examine what causes chimney corrosion and how we can stop it. With a little knowledge and regular maintenance, we can protect our investment. This will help us keep our homes warm and safe. We’ll also look at how to extend the life of our chimneys. Plus, we’ll explore ways to improve the performance of our oil-burning appliances.

How Corrosion Affects Oil-Burning Appliance Chimneys: What You Need to Know

Corrosion in oil-burning appliance chimneys is more than just an inconvenience. It’s a real threat! When oil burns, it produces acidic condensation. This can cause corrosion in the chimney flue. Over time, this weakens the chimney. It can also lead to hazards, like rust in the flue.

The high humidity and cold winters add to the problem. The combination of cold air and warm exhaust causes acidic condensation to form. This acts like an uninvited guest at a party, silently damaging the chimney.

Key issues caused by corrosion in oil-burning chimneys include:

- Blockages: Corrosion can lead to debris buildup, causing blockages.

- Efficiency Loss: Weakened chimneys can impact the oil burner’s performance.

- Safety Risks: Rust in the flue can increase carbon monoxide risk.

Oil-burning chimneys must be regularly maintained by homeowners in the Garden State. Corrosion prevention includes a few important steps. First, get regular professional inspections. This helps spot problems early. Next, ensure proper ventilation. It keeps moisture from building up. Lastly, use corrosion-resistant materials. They help prevent damage over time. For more information, check the National Fire Protection Association or Chimney Safety Institute of America.

Causes of Corrosion

Corrosion in oil-burning chimney systems can create serious issues, compromising efficiency and safety. Understanding its causes helps tackle these problems effectively. Reach out to professionals for consultation.

Combustion Byproducts

When oil burns, it produces combustion byproducts that accelerate chimney flue corrosion. These byproducts, laden with acidic compounds, eat away at the chimney’s insides. Over time, this damage may lead to rust in the chimney flue, affecting performance. Regular maintenance can help mitigate this, so don’t ignore those strange smells! For more info, check out the Chimney Safety Institute of America.

Moisture and Condensation

Moisture plays a sneaky role in oil burner exhaust corrosion. When warm exhaust hits cold chimney walls, it creates condensation. Moisture mixes with combustion acids to create corrosive elements, which can damage the chimney flue. This is a real risk, especially in chilly winters. Proper ventilation is key to combatting this issue. See more at the National Fire Protection Association.

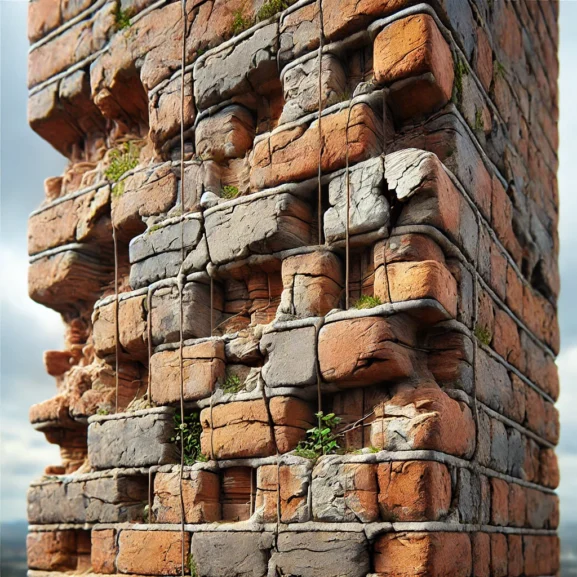

Chimney Material Vulnerability

Different materials react differently to acidic condensation. Clay and brick chimneys are especially vulnerable, while stainless steel offers better resistance. Understanding material weaknesses ensures timely intervention in the ongoing maintenance of oil-burning chimneys. If your chimney has moved independently due to rust, it might be time for professional help! Choose materials wisely to prevent future woes.

Effects of Corrosion

Corrosion in oil-burning appliance chimneys can lead to several issues. These problems can result in costly repairs and can be dangerous. Understanding these effects helps homeowners take timely action. Unique weather conditions make this even more crucial.

Structural Integrity

Corroded chimneys lose their sturdiness, which could lead to collapse without regular maintenance. Materials like clay and brick deteriorate faster due to acidic condensation. Over time, cracks and holes appear in the chimney walls, weakening the structure. This allows for moisture infiltration, worsening corrosion. Structural damage isn’t just an eyesore; it’s a ticking time bomb. Check out the Chimney Safety Institute of America for more details. To keep your chimney standing tall, reach out to professionals for consultation.

Safety Concerns

The risk of safety hazards rises significantly with chimney flue corrosion. Rust in the chimney flue can lead to blockages. These blockages can trap dangerous gases, such as carbon monoxide. This can make the air inside your home unsafe. And, let’s face it, nobody’s fond of unexpected tendencies to nap forever. Fires can start when creosote deposits ignite, posing severe risks. Regular inspections and maintenance are essential, like those detailed by the National Fire Protection Association. Give us a call to make sure your chimney is safe. Reach out to professionals for consultation.

Prevention Methods

Repair and Replacement Options

Corrosion in oil-burning chimneys is a common issue. The cold winters and humid summers make it worse. These weather conditions cause the chimney materials to break down over time. The moisture from the humidity mixes with oil residue, leading to rust and corrosion. This can affect the chimney’s performance and safety. It is important to monitor and maintain chimneys regularly to prevent damage. Our solutions focus on identifying and addressing chimney flue corrosion effectively.

Identifying Damage

Spotting damage early keeps repairs simple and costs low. Signs of oil-burning chimney corrosion may include:

- Rust in chimney flue

- Cracks in the flue liner

- Discolored brickwork

- Moisture stains

A professional inspection pinpoints these issues, preventing more severe damage. If you notice these symptoms, reach out to professionals for consultation.

Repair Solutions

Several repair solutions tackle chimney flue corrosion. We avoid DIY tips here because, trust us, your chimney doesn’t need a DIY haircut.

- Re-lining: Installing a new liner, especially stainless steel, resists future corrosion.

- Joint repairs: Sealing or replacing damaged joints to stop leaks

- Rust removal: Clearing corrosion and applying protective coatings to guard against acidic condensation

A professional applies these solutions efficiently, ensuring lasting results. Consult the Chimney Safety Institute of America and NFPA for expert guidance and safety tips.

Chimney Replacement Considerations

When damage extends beyond repair, replacement becomes a priority. Consider these factors:

- Material: Opt for stainless steel linings for maximum resilience

- Cost: Calculate both initial and long-term maintenance expenses

- Design: Ensure proper ventilation to manage oil burner exhaust corrosion

Replacement ensures safety and efficiency, avoiding the unappealing “chimney slip ‘n fall.” Our team provides custom solutions for homeowners and is here to guide you through every step.

For a free consultation and professional advice, reach out to professionals.

Conclusion

Addressing corrosion in oil-burning appliance chimneys is important for our safety and efficiency. Corrosion can cause damage over time, so we need to understand how it happens and what it does. Regular inspections and maintenance help prevent corrosion. Using materials that resist corrosion also plays a big part. When we hire professionals, they can spot any damage early and fix it before it gets worse. This keeps repair costs lower. Let’s take care of our chimneys to avoid hazards and keep everything running well. For more help, we can look at resources from trusted groups. The National Fire Protection Association and the Chimney Safety Institute of America are two good options.

Frequently Asked Questions

Why is chimney maintenance for oil-burning appliances important?

Maintaining your chimney for oil-burning appliances is very important. If you neglect it, you could face issues like blockages, inefficiency, and safety risks. One major risk is carbon monoxide leaks. Burning oil can cause acidic condensation, which speeds up corrosion. Regular maintenance helps prevent these problems. It keeps the chimney strong and safe by stopping corrosion.

How does corrosion affect chimneys associated with oil-burning appliances?

Corrosion can affect chimneys in several ways. It causes blockages and reduces efficiency, and it also creates safety risks. Acidic compounds from combustion and moisture cause rust and structural damage. If left unchecked, this can lead to a chimney collapse. Regular inspections and maintenance are important to manage corrosion.

What materials are most resistant to chimney corrosion?

Stainless steel resists chimney corrosion better than clay and brick. It might cost more at first, but it lasts longer. Stainless steel liners are strong and can handle acidic condensation, making them a good choice for the long term.

What are the signs of chimney corrosion that homeowners should watch for?

As homeowners, we should watch out for signs like rust in the flue, cracks, discolored brickwork, and moisture stains. These signs can point to corrosion and possible structural damage. Getting a professional inspection and repair is important as soon as possible. This will help prevent more serious problems later on.

How can homeowners prevent chimney corrosion?

You can prevent chimney corrosion by having regular professional inspections. Use stainless steel liners and apply protective coatings. Make sure there is proper ventilation. Annual maintenance is important. It helps to catch issues early. This will extend the life of your chimney.

What steps should be taken if a chimney is too damaged to repair?

Why is chimney maintenance for oil-burning appliances important?

Maintaining your chimney for oil-burning appliances is very important. If you neglect it, you could face issues like blockages, inefficiency, and safety risks. One major risk is carbon monoxide leaks. Burning oil can cause acidic condensation, which speeds up corrosion. Regular maintenance helps prevent these problems. It keeps the chimney strong and safe by stopping corrosion.

How does corrosion affect chimneys associated with oil-burning appliances?

Corrosion can affect chimneys in several ways. It causes blockages and reduces efficiency, and it also creates safety risks. Acidic compounds from combustion and moisture cause rust and structural damage. If left unchecked, this can lead to a chimney collapse. Regular inspections and maintenance are important to manage corrosion.

What materials are most resistant to chimney corrosion?

Stainless steel resists chimney corrosion better than clay and brick. It might cost more at first, but it lasts longer. Stainless steel liners are strong and can handle acidic condensation, making them a good choice for the long term.

What are the signs of chimney corrosion that homeowners should watch for?

As homeowners, we should watch out for signs like rust in the flue, cracks, discolored brickwork, and moisture stains. These signs can point to corrosion and possible structural damage. Getting a professional inspection and repair is important as soon as possible. This will help prevent more serious problems later on.

How can homeowners prevent chimney corrosion?

You can prevent chimney corrosion by having regular professional inspections. Use stainless steel liners and apply protective coatings. Make sure there is proper ventilation. Annual maintenance is important. It helps to catch issues early. This will extend the life of your chimney.

How often should chimneys associated with oil-burning appliances be inspected?

We recommend inspecting chimneys once a year. A professional inspection can spot early signs of corrosion and find other issues. This helps you make repairs on time, prevent serious damage, and keep your home safe.