Preventing and Managing Rusting of Steel Chimney Liners: Tips for Long-lasting Safety

When it comes to the cozy warmth of a fireplace, we often overlook the crucial role of steel chimney liners. These unsung heroes, but, face a persistent enemy—rust. As steel chimney liners are exposed to moisture and combustion byproducts, rusting becomes a significant concern. This not only affects their longevity but also raises safety issues.

Understanding why rust occurs and how it impacts our chimney systems is essential for maintaining a safe and efficient fireplace. We’ll explore the causes of rust in steel chimney liners and discuss preventive measures to extend their lifespan. By staying informed, we can ensure our homes remain both warm and safe.

A Comprehensive Guide to Steel Chimney Liners

Steel chimney liners play a crucial role in keeping our homes warm and safe. Their durability makes them a popular choice, but they face challenges like rusting issues. Let’s jump into essential aspects of maintaining these liners.

Rusting Issues

Steel liners often face rust due to moisture intrusion. When damp weather meets metal, rust blossoms like an unwanted garden. This rust not only weakens material durability but also affects the lifespan of liners. Staying aware of these rusting issues helps in planning timely chimney repairs.

Corrosion Prevention

To battle corrosion, liner maintenance is key. Regular inspections identify problem areas early. For expert care reach out to professionals for consultation. Surprisingly, vinegar isn’t just for salads; it can sometimes clean smaller rust spots.

Liner Maintenance

Routine maintenance extends the liner’s life. Check for signs of moisture and metal degradation. Ignoring these signs is like skipping dentist appointments—it gets painful (and expensive). For comprehensive care tips, refer to resources like Chimney Safety Institute of America.

Considerations

In our lovely Garden State, weather impacts chimneys uniquely. Frequent temperature changes demand vigilant monitoring and potential chimney upgrades. We advise contacting professionals for any repair needs.

Remember, we’re not advising on DIY fixes. Keep amusing surprises for parties, not chimneys. For personalized assistance, reach out for that free consultation.

Causes of Rusting in Steel Chimney Liners

Rusting in steel chimney liners affects liner maintenance and system safety. Understanding the main causes helps in planning for effective maintenance and corrosion prevention.

Environmental Factors

Steel chimney liners face tough weather. High humidity and temperature fluctuations increase rusting issues. Moisture intrusion from rain or snow accelerates metal degradation. Chimney liners should shield against elements to extend their lifespan. In comparison, homes in arid climates don’t face this intensity of moisture exposure.

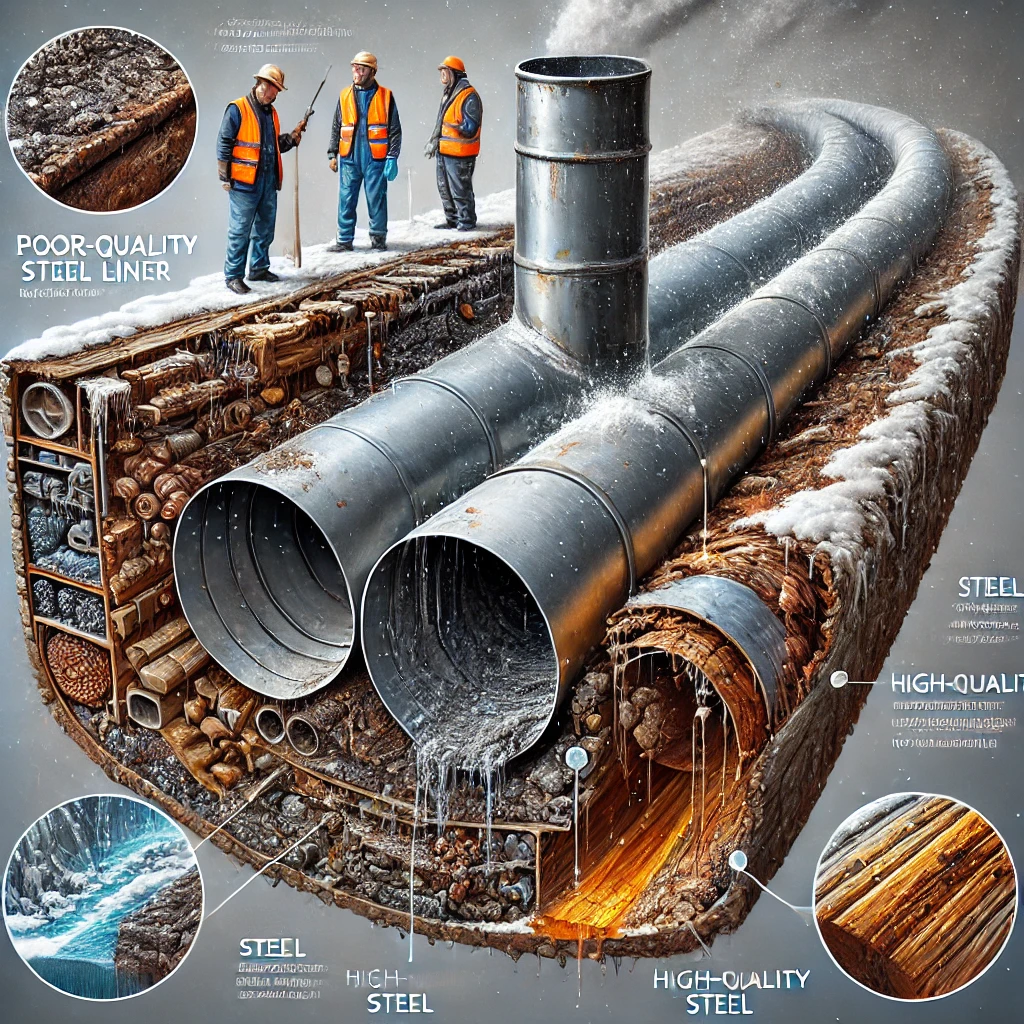

Material Quality

Material durability plays a crucial role in rust prevention. High-quality steel resists corrosion better than lower-grade metals. Unfortunately, some liners contain inferior alloys, making them prone to rusting issues. Many manufacturers offer different steel grades; opting for premium grades reduces degradation risks. Quality installation matters too. It ensures proper fitting and sealing against environmental factors. Check our offerings for durable chimney liners that withstand fickle weather by reaching out to professionals for consultation.

Maintenance Practices

Regular maintenance practices help in prolonging the lifespan of liners. Regular inspections catch early signs of rust, avoiding costlier chimney repairs later. Routine cleaning clears debris that might trap moisture, enhancing liner performance. Simple? Yes, but waving a magic wand’s not enough—no DIYs here! Trust experienced professionals to handle this. Correct maintenance includes addressing minor rust spots promptly. For maintenance tips, check US Fire Administration’s guidelines. Call us for a free consultation and ensure your chimneys are in top shape.

Effects of Rusting on Chimney Performance

Rusting in steel chimney liners can seriously compromise chimney performance. When rust sets in, the liner’s ability to contain harmful gases decreases. This can lead to dangerous leaks. This isn’t just a small hiccup; it puts every marshmallow roast at stake.

- Reduced Efficiency: Rusting issues hinder the liner’s ability to efficiently channel smoke, increasing creosote buildup. This results in greater chances of chimney fires.

- Structural Damage: Uncontrolled rust can weaken the liner’s structure, causing the masonry to degrade. Metal degradation over time can make a repair, not an upgrade, a pressing need.

- Increased Maintenance Costs: Ignoring rust can lead to costly chimney repairs. Regular liner maintenance extends the chimney’s lifespan, avoiding emergency repairs.

Rust is sneaky, often starting with moisture intrusion from rain or snow. Once rust takes hold, quick action’s necessary.

For premium service and corrosion prevention, we recommend scheduling regular inspections. Ask us how vinegar could fit into your maintenance routine, or better yet, call for a consultation.

Inspection and Detection of Rust

Regular inspections are crucial to keep steel chimney liners in top shape. Rusting issues sneak up fast if not spotted early.

Visual Inspections

Visual checks offer a quick way to spot signs of rust. Start by looking for red or brown patches on the liner surface. These patches signal metal degradation from moisture intrusion. Check connections and joints where rust likes to hide. Don’t ignore any signs, even if they seem minor. Remember, tiny rust spots grow into big problems.

Pro tip: Avoid mistaken rust for stubborn pizza sauce splashes during visual inspections. If in doubt, reach out to professionals for consultation.

Advanced Detection Methods

When visual inspections fall short, advanced methods help us uncover hidden rust. We use specialized cameras to probe hard-to-reach areas. These cameras reveal corrosion inside the liner that’s not visible outside. Regular liner maintenance with these tools ensures a longer lifespan of liners.

We employ further diagnostic techniques, like ultrasonic testing, to measure liner thickness. Thinner spots suggest rust damage and potential for chimney repairs.

As always, reach out to professionals for consultation to address corrosion prevention concerns in your home deftly.

Preventive Measures Against Rusting

Steel chimney liners need regular check-ups to prevent rust from raining on the parade. Without maintenance, rusting issues can lead to costly chimney repairs. Let’s jump into ways to keep liners rust-free.

Regular Maintenance Routines

Our first line of defense is consistent maintenance. Regular maintenance ensures the longevity of liners and keeps metal degradation at bay.

- Inspections: Regularly inspect steel chimney liners for any signs of rust. In areas, where weather swings like a pendulum, inspections are crucial.

- Cleaning: Sweep away soot and debris, those pesky rust accelerators.

- Professional Help: We strongly advise against DIY maintenance. Reach out to professionals for consultation. Our professionals have the expertise needed to perform thorough maintenance.

Use of Protective Coatings

Protective coatings act as an armor for steel liners, shielding them from the elements.

- Sealants: Apply moisture-resistant sealants to combat moisture intrusion. This is especially important in areas with high humidity.

- High-Quality Products: Use top-tier coatings known for their durability. Lower-grade options can’t withstand the test of time.

- Professional Application: An improperly applied coating can turn into a comedic nightmare. Leave it to the professionals for best results.

Keep your chimneys in top-notch condition with these measures.

Repair and Replacement Options

Deciding whether to repair or replace steel chimney liners can be tricky. Rusting issues, especially in areas with humid climate, can make this decision even harder.

When to Repair vs. Replace

- Minor Rust Spots: Repair minor corrosion by cleaning and applying a protective coating. If metal degradation is minimal, repairs extend the lifespan of liners.

- Significant Damage: Replace liners showing severe rusting or structural damage. A compromised liner can lead to harmful gas leaks and reduced chimney efficiency.

Humor may not repair chimneys, but it sure makes reading about them more fun! When in doubt, reach out to professionals for consultation.

Choosing the Right Materials

Selecting materials impacts liner maintenance and durability. High-quality steel withstands corrosion better than cheaper alternatives.

- High-Grade Steel: Offers superior strength and rust resistance; ideal for high moisture areas.

- Alternative Liners: Consider clay or cast-in-place liners if steel’s not suitable, but be mindful of their pros and cons.

Chimney upgrades with the right materials prevent future issues.

Preventing Rust in Steel Chimney Liners: Essential Tips for Safety and Efficiency

Rusting of steel chimney liners poses significant risks to both safety and efficiency, especially in humid climates. By understanding the causes and taking proactive measures, we can effectively combat corrosion. Regular inspections and maintenance are crucial in identifying early signs of rust and preventing severe damage. It’s essential to use high-quality materials and protective coatings to enhance durability. When rust issues arise, timely repairs or replacements with superior-grade liners are vital. Let’s prioritize our home’s safety by staying informed and seeking professional guidance to maintain our chimney systems in top condition.

Frequently Asked Questions

Why is a steel chimney liner important for fireplaces?

A steel chimney liner is crucial for maintaining a safe and efficient fireplace. It protects the chimney walls from heat and corrosion, contains harmful gases, and helps improve the overall efficiency of the fireplace. Without a proper liner, there’s an increased risk of chimney fires due to creosote buildup and potential gas leaks.

What causes rusting in steel chimney liners?

Rusting in steel chimney liners is primarily caused by exposure to moisture and combustion byproducts. Environmental factors like humidity, temperature fluctuations, and moisture intrusion from rain or snow also contribute significantly. These factors weaken the liner’s material over time, leading to rust and corrosion.

How can homeowners prevent rust in chimney liners?

Homeowners can prevent rust in chimney liners by scheduling regular inspections and maintenance. Applying moisture-resistant sealants, using high-quality materials, and ensuring proper installation can also help. Routine cleaning, visual checks for rust, and seeking professional advice for preventive measures are essential to combat corrosion.

Is rust on a chimney liner dangerous?

Yes, rust on a chimney liner is dangerous. It can compromise the liner’s ability to contain harmful gases, leading to potential leaks and chimney fires. Rust also reduces the liner’s structural integrity, increasing the risk of costly repairs and decreased fireplace efficiency.

How often should chimney liners be inspected for rust?

Chimney liners should be inspected at least once a year. Regular inspections help detect early signs of rust, such as red or brown patches. Professional evaluations, including advanced detection methods like specialized cameras, are recommended to assess the liner’s condition thoroughly, especially in high-humidity areas.

What should I do if I notice rust on my steel chimney liner?

If you notice rust on your steel chimney liner, address it promptly. Clean minor rust spots with solutions like vinegar and schedule a professional inspection for a comprehensive evaluation. Depending on the severity, repairs or a replacement may be necessary to prevent further damage and ensure safety.

Are there alternatives to steel chimney liners?

Yes, alternatives to steel chimney liners include clay and cast-in-place liners. These options may offer better resistance to moisture and corrosion, depending on the climate and specific needs of your home. Consult with a professional to determine the most suitable liner material for your chimney system.

Why is professional maintenance important for chimney liners?

Professional maintenance is essential for chimney liners because it ensures thorough inspections and effective preventive measures against rust and corrosion. Experienced professionals can apply protective coatings properly, assess the condition accurately, and offer solutions to extend the liner’s lifespan, keeping your home safe and efficient.